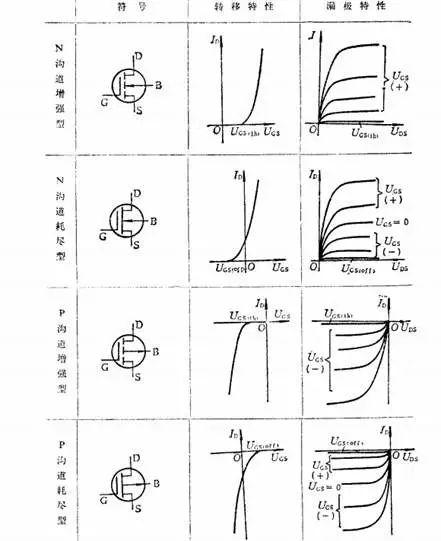

Labada sababood ee ugu waaweynof MOSFET guuldarro:

Voltage failure: taasi waa, korantada BVdss ee u dhaxaysa qulqulka iyo isha ayaa ka badan tamarta la qiimeeyay eeMOSFET oo gaadhay awood gaar ah, taasoo keenaysa MOSFET inay fashilanto.

Cilladda Korantada ee Albaabka: Albaabku waxa soo gaadhay koronto aan caadi ahayn, taasoo keentay in lakabka ogsijiinta ee albaabku xumaado.

Khaladka burburka (voltage failure)

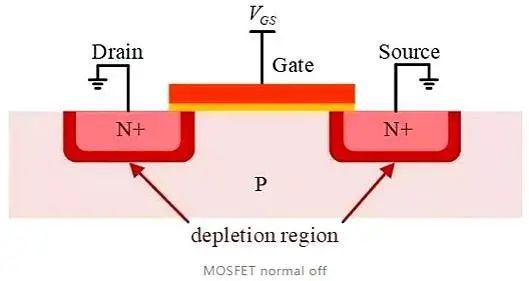

Waa maxay dhab ahaantii burburka barafku? Si fudud u dhig,MOSFET waa hab guuldarraysa oo uu abuuray booska sare ee u dhexeeya danabyada baska, danabyada milicsiga beddelka, danabyada sare u kaca, iwm. iyo MOSFET. Marka la soo koobo, waa guuldarro caam ah oo timaadda marka danabka ku jira tiirka isha biya-mareenka ee MOSFET uu dhaafo qiimihii danabkeeda ee la cayimay oo uu gaaro xad tamareed gaar ah.

Tallaabooyinka looga hortagayo waxyeelada barafku:

-Yaree qiyaasta si habboon. Warshadahan, inta badan waa la dhimay 80-95%. Dooro ku salaysan shuruudaha dammaanadda ee shirkadda iyo mudnaanta khadka.

Danab milicsi waa macquul.

-RCD, naqshadeynta wareegga nuugista TVS waa macquul.

-Xadhkaha hadda sarreeya waa inuu ahaadaa mid weyn intii suurtagal ah si loo yareeyo inductance parasitic.

-Dooro iska caabiyaha albaabka ku habboon Rg.

-Ku dar qoyaanka RC ama nuugista diode Zener ee sahay koronto oo sarreeya haddii loo baahdo.

Gate Voltage Failure

Waxaa jira saddex sababood oo waaweyn oo keena koronto aan caadi ahayn oo sarreeya: koronto taagan inta lagu jiro wax soo saarka, gaadiidka iyo isu-ururinta; resonance danab sare oo ay abuuraan xuduudaha dulin ee qalabka iyo wareegyada inta lagu guda jiro hawlgalka nidaamka korontada; iyo u gudbinta danab sare iyada oo loo marayo Ggd ilaa shabkada inta lagu jiro shoog danab sare ah (cillad aad u badan inta lagu jiro tijaabada garaacista hillaaca).

Tallaabooyinka looga hortagayo cilladaha korantada albaabka:

Ilaalinta xad-dhaafka ah ee u dhexeeya albaabka iyo isha: Marka is-hortaagga u dhexeeya albaabka iyo isha uu aad u sarreeyo, isbeddelka degdegga ah ee korantada ee u dhexeeya albaabka iyo isha ayaa lagu lammaaniyaa albaabka iyada oo loo marayo awoodda u dhaxaysa electrodes, taasoo keentay koronto UGS aad u sarreeya oo xad-dhaaf ah, taasoo horseedaysa nidaaminta iridda. Waxyeelada oksaydhka ee joogtada ah. Haddii UGS ay ku jirto danab ku meel gaar ah oo togan, qalabku wuxuu kaloo keeni karaa khaladaad. Sidan oo kale, xannibaadda wareegga wadista albaabka waa in si habboon loo dhimaa oo iska caabiyaha qoyaanka ah ama korantada xasilinta 20V waa in lagu xidhaa inta u dhaxaysa albaabka iyo isha. Waa in taxadar gaar ah la sameeyaa si looga hortago qalliinka albaabka furan.

Ilaalinta xad-dhaafka ah ee u dhexeeya tuubooyinka dareeraha: Haddii uu jiro inductor wareegga wareegga, isbeddel degdeg ah oo ku yimaada qulqulka hadda (di/dt) marka unugga la damiyo waxay keeni doontaa in korontadu ay si fiican u korto tamarta sahayda, taasoo dhaawac u geysanaysa cutubka. Ilaalinta waa inay ku jirtaa xajinta Zener, RC clamp, ama wareegga xakamaynta RC.