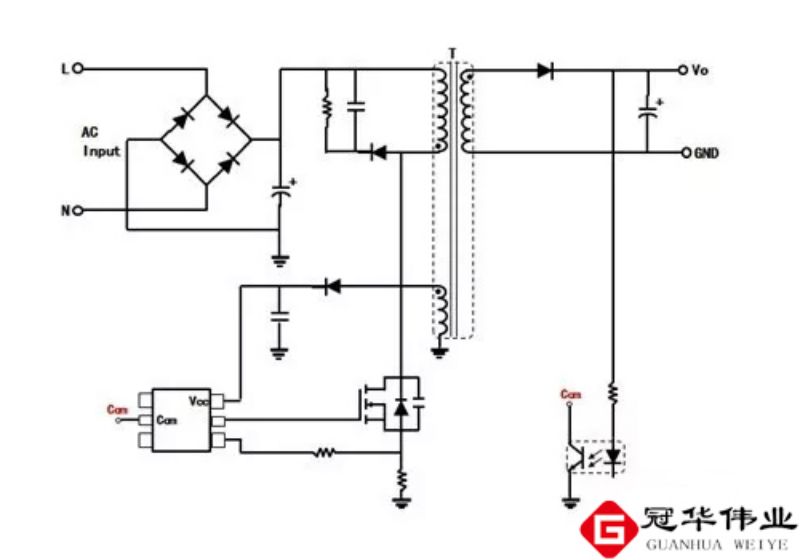

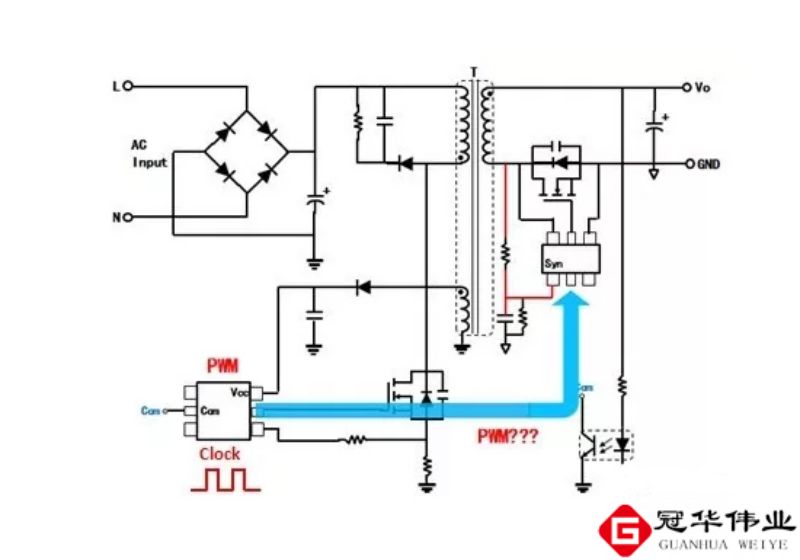

Qaab dhismeedka tamarta aasaasiga ah eesi degdeg ah u dallacaaddaQC waxay isticmaashaa dib-u-soo-baxa + dhinaca sare (sare) sixitaanka isku-dhafka ah ee SSR. Beddeleyaasha duullimaadyada, marka loo eego habka muunad-celinta jawaab-celinta, waxa loo qaybin karaa: xeerka dhinaca aasaasiga ah (primary) iyo xeerka dhinaca labaad (sare); iyadoo loo eegayo meesha uu ku yaal kontaroolaha PWM. Waxa loo qaybin karaa: kontoroolka dhinaca hoose (primary) iyo kan labaad (secondary side). Waxay u muuqataa in aanay waxba ku lahayn MOSFET. Haddaba,Olukeywaa in la waydiiyaa: Aaway MOSFET? Doorkee ayay ka qaadatay?

1. Is-habaynta dhinaca hore (primary) iyo habaynta dhinaca labaad (labaad).

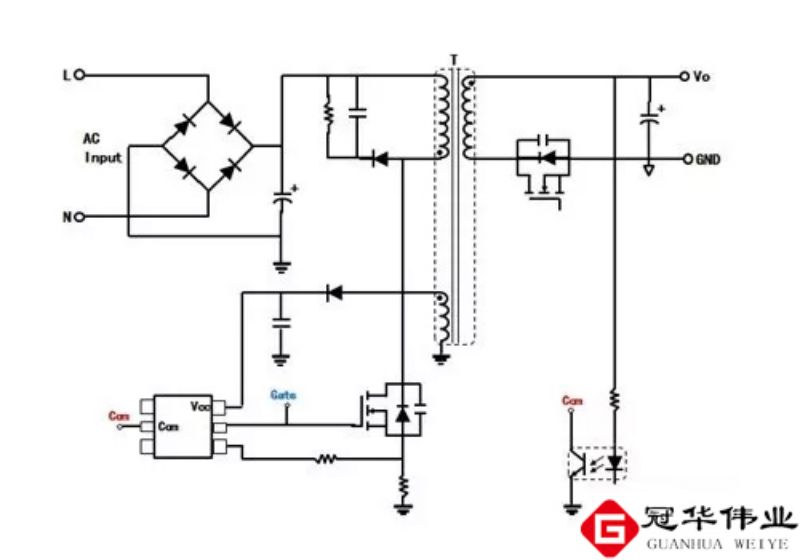

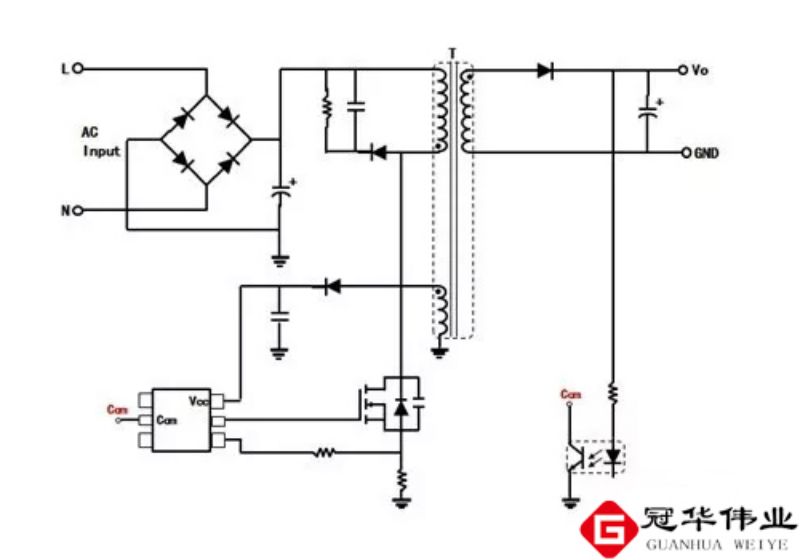

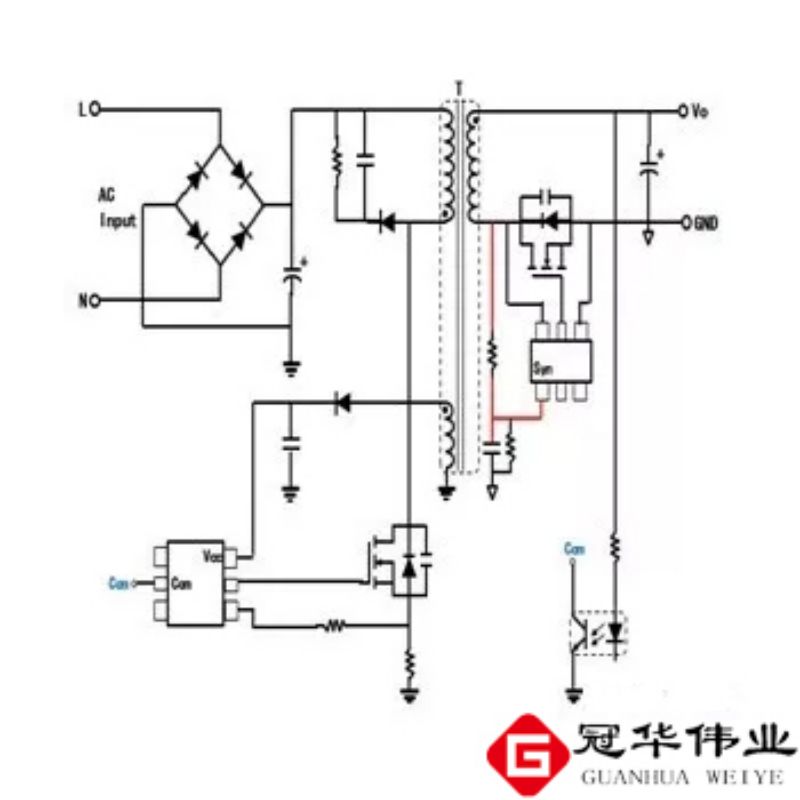

Xasiloonida korantada wax-soo-saarka waxay u baahan tahay xiriir-celin-celin si loogu diro macluumaadkeeda isbeddelka ah kontaroolaha ugu weyn ee PWM si uu u hagaajiyo isbeddellada tamarta gelinta iyo culeyska soo-saarka. Marka loo eego hababka muunad-celinta jawaab-celinta ee kala duwan, waxa loo qaybin karaa habaynta dhinaca aasaasiga ah (primary) iyo habaynta dhinaca labaad (labaad), sida ku cad jaantusyada 1 iyo 2.

Calaamadaha jawaab celinta ee xeerka dhinaca aasaasiga ah si toos ah loogama soo qaadan korantada wax soo saarka, laakiin laga soo bilaabo dabaysha kaaliyaha ama dabaysha aasaasiga ah ee ilaalinaysa xidhiidh saamile gaar ah oo la leh danab wax soo saarka. Astaamihiisu waa:

① Habka jawaab celinta tooska ah, heerka xakamaynta culeyska oo liita iyo saxnaanta liidata;

② Kharash fudud oo hooseeya;

③ Looma baahna xidhidhiyaha indhaha.

Calaamadaha jawaab celinta ee qaanuunka dhinaca sare (sare) waxaa si toos ah looga soo qaadaa korantada wax soo saarka iyadoo la adeegsanayo muraayadaha indhaha iyo TL431. Astaamihiisu waa:

① Habka jawaab celinta tooska ah, heerka xakamaynta culeyska wanaagsan, heerka nidaaminta tooska ah, iyo saxnaanta sare;

② Wareegga hagaajintu waa mid adag oo qaali ah;

③ Waa lagama maarmaan in la go'doomiyo muraayadaha indhaha, kaas oo leh dhibaatooyinka gabowga waqti ka dib.

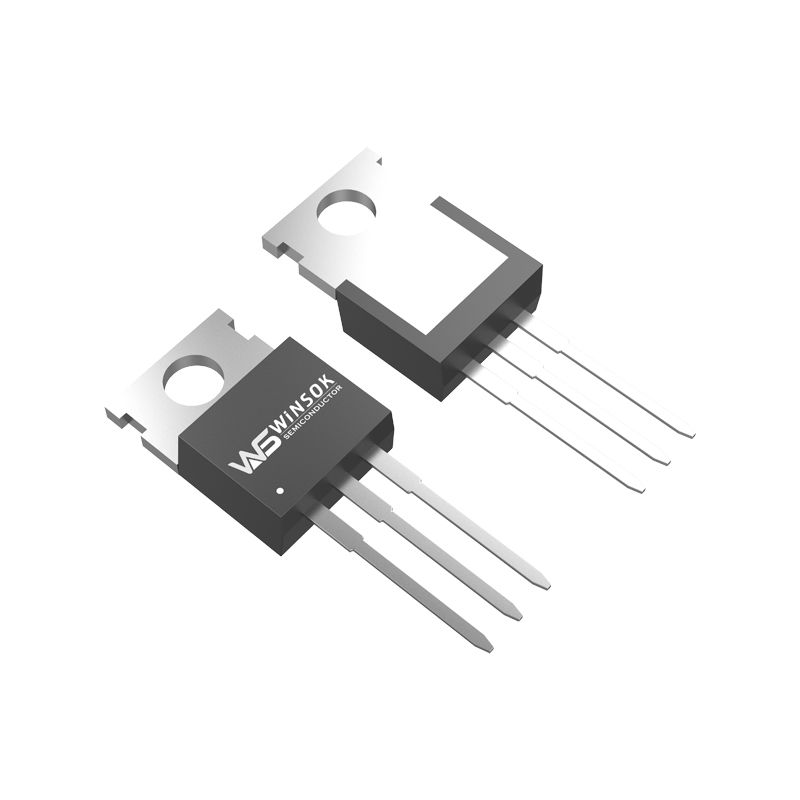

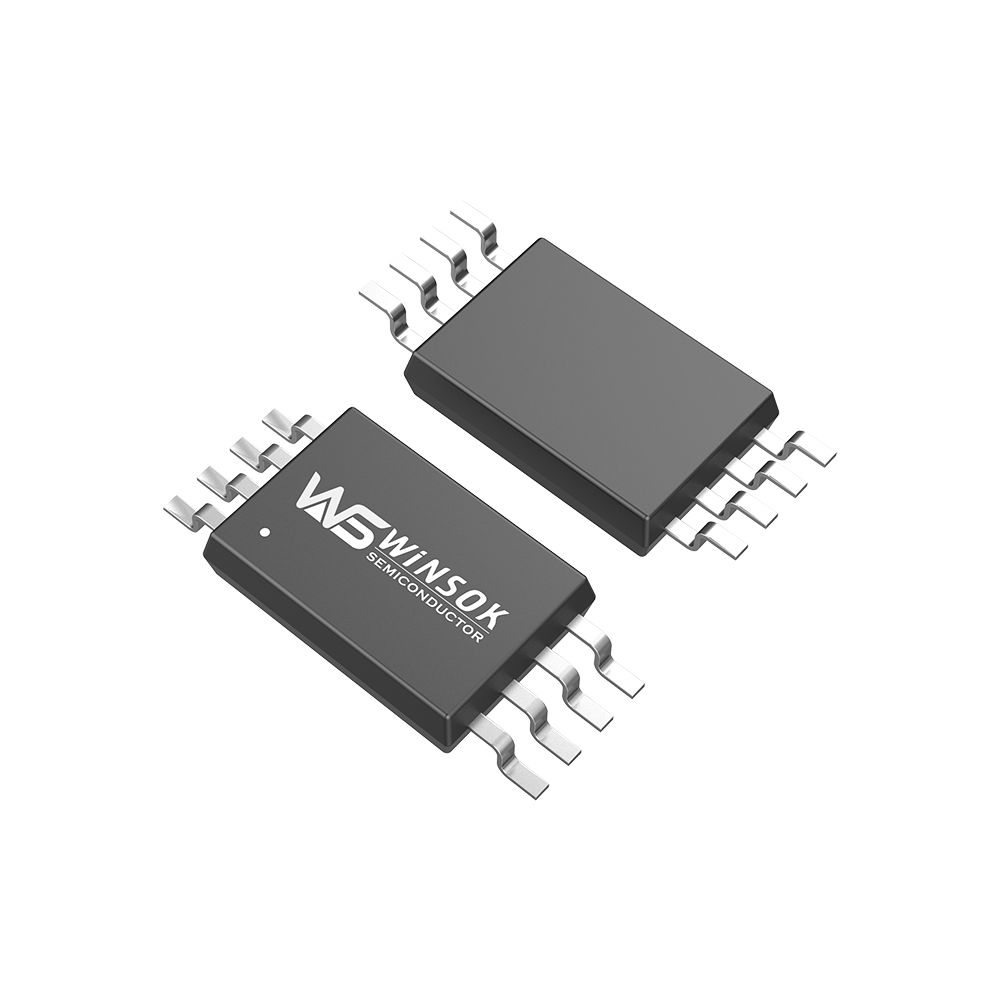

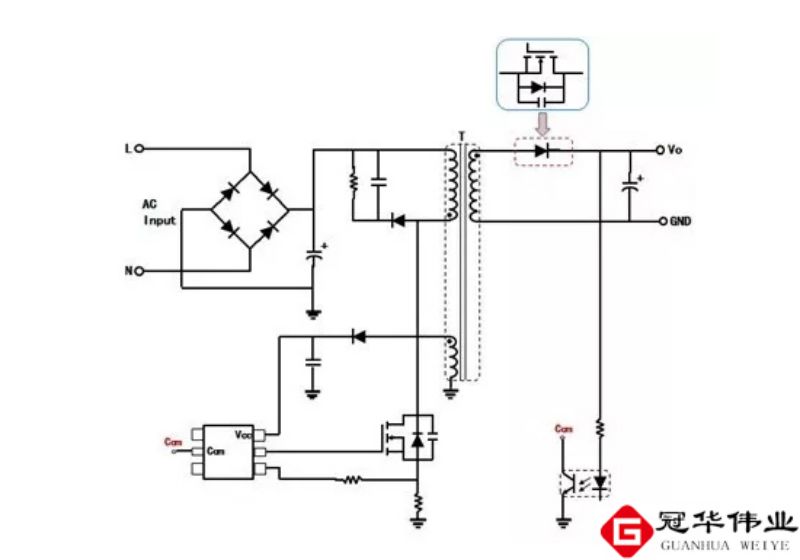

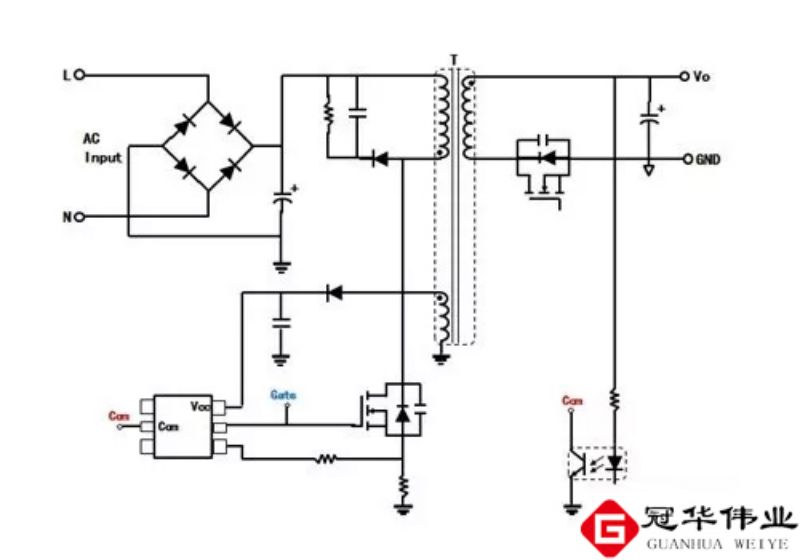

2. Dhinaca labaad (secondary) hagaajinta diode iyoMOSFETsixitaanka isku midka ah ee SSR

Dhinaca labaad (sare) ee beddelaha duuliyaha badanaa waxay isticmaashaa hagaajinta diode sababtoo ah wax soo saarka ballaaran ee hadda ku dallacaadda. Gaar ahaan dallacaadda tooska ah ama dallacaadda fiishka ah, wax-soo-saarka hadda wuxuu u sarreeyaa ilaa 5A. Si loo hagaajiyo waxtarka, MOSFET waxa loo isticmaalaa beddelka diode sida hagaajinta, kaas oo loo yaqaan 'secondary (secondary) synchronous rectification SSR, sida ku cad jaantusyada 3 iyo 4.

Astaamaha dhinaca labaad (sare) hagaajinta diode:

① Fudud, looma baahna kantaroole dheeri ah, kharashkuna waa yar yahay;

② Marka wax soo saarka hadda uu weyn yahay, waxtarku wuu hooseeyaa;

③ Kalsoonida sare.

Sifooyinka dhinaca sare (sare) MOSFET hagaajinta isku midka ah:

① Isku-dhafan, oo u baahan kontaroolaha wadista dheeraadka ah iyo kharash sare;

② Marka hadda wax soo saarka uu weyn yahay, waxtarku waa sarreeyaa;

③ Marka la barbar dhigo diode-yada, isku haleentoodu waa yar tahay.

Codsiyada la taaban karo, MOSFET ee saxitaanka isku midka ah ee SSR waxaa badanaa laga raraa cidhifka sare ilaa dhamaadka hoose si loo fududeeyo wadista, sida ku cad Jaantuska 5.

Tilmaamaha MOSFET-dhamaadka sare ee sixitaanka isku-dhafka ah ee SSR:

① Waxay u baahan tahay bootstrap drive ama wadista sabaynaysa, taas oo kharash badan;

② EMI wanaagsan

Astaamaha hagaajinta isku midka ah ee SSR MOSFET ee la dhigo dhamaadka hoose:

① Wadista tooska ah, wadista fudud iyo kharash yar;

② EMI liidata.

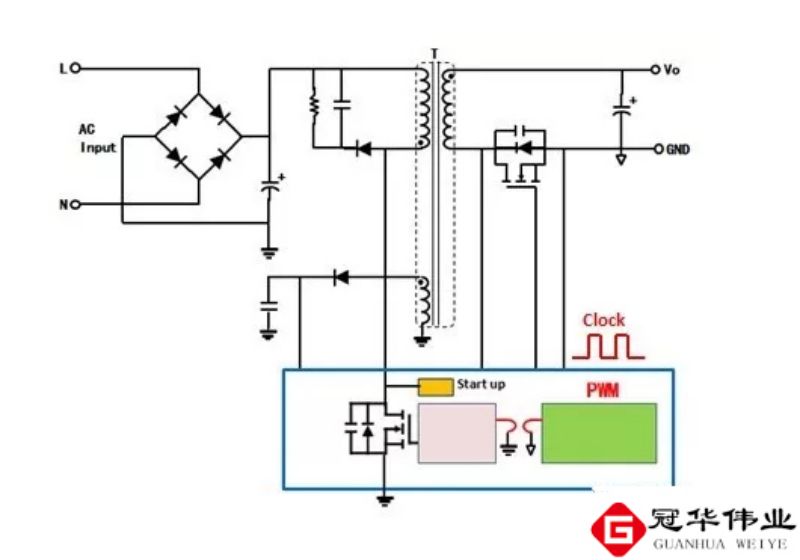

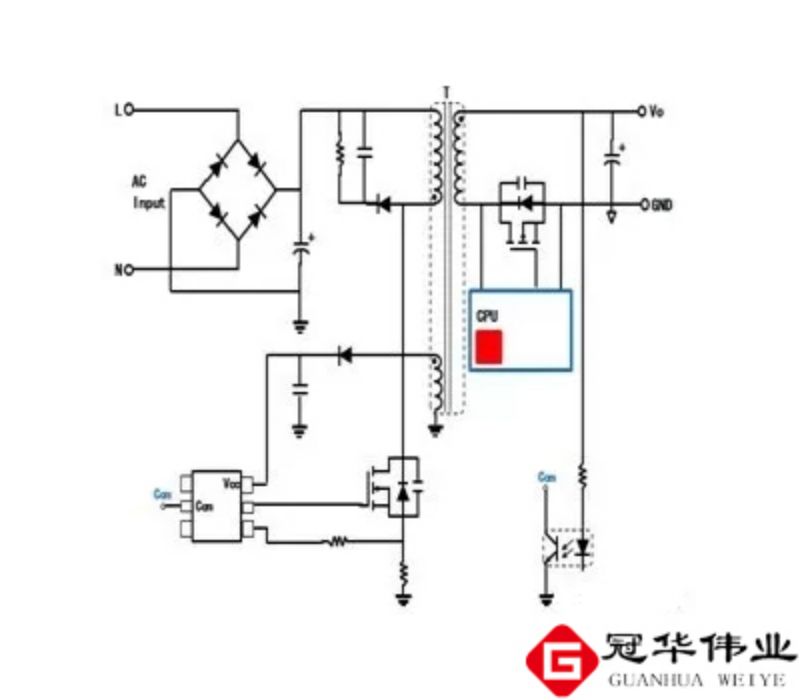

3. Kantaroolka dhinaca koowaad (primary) iyo kan labaad (labaad).

Koontaroolaha ugu weyn ee PWM waxa la dhigayaa dhinaca koowaad (primary). Qaab dhismeedkan waxa loo yaqaan kontoroolka dhinaca hoose (primary). Si loo hagaajiyo saxnaanta korantada wax soo saarka, heerka xakamaynta culeyska, iyo heerka qawaaniinta tooska ah, kontoroolka dhinaca aasaasiga ah (primary) wuxuu u baahan yahay indho-indheyn dibadeed iyo TL431 si loo sameeyo isku xirka jawaab celinta. Xawaaraha nidaamka waa yar yahay xawaaraha jawaabtuna waa mid gaabis ah.

Haddii kontaroolaha ugu weyn ee PWM la dhigo dhinaca labaad (labaad), optocoupler-ka iyo TL431 waa laga saari karaa, korantada wax soo saarka si toos ah ayaa loo xakameyn karaa loona hagaajin karaa jawaab degdeg ah. Qaab dhismeedkan waxaa lagu magacaabaa kantaroolka sare (secondary).

Astaamaha xakamaynta dhinaca aasaasiga ah (primary):

① Optocoupler iyo TL431 ayaa loo baahan yahay, iyo xawaaraha jawaabtu waa mid gaabis ah;

② Xawaaraha ilaalinta wax soo saarku waa gaabis.

③ Habka toosinta isku-dhafka ah ee CCM, dhinaca labaad (labaad) wuxuu u baahan yahay calaamad is-waafajin.

Astaamaha xakamaynta sare (sare):

① Wax-soo-saarka si toos ah ayaa loo ogaanayaa, looma baahna optocoupler iyo TL431, xawaaraha jawaabtu waa dhakhso, xawaaraha ilaalinta wax-soo-saarkuna waa dhakhso;

② Dhanka labaad (sare) hagaajinta isku dhafan MOSFET si toos ah ayaa loo wadaa iyada oo aan loo baahnayn calaamadaha is-waafajinta; Aaladaha dheeraadka ah sida transformers-ka garaaca wadnaha, isku-xidhayaasha magnetic ama lamaanayaasha awooda ayaa loo baahan yahay si ay u gudbiyaan calaamadaha wadista ee dhinaca hore (primary) MOSFET-sare.

③ Dhinaca aasaasiga ah (primary) wuxuu u baahan yahay wareegga bilawga ah, ama dhinaca labaad (sare) wuxuu leeyahay sahay koronto ah oo lagu bilaabo.

4. Habka CCM ee joogtada ah ama habka DCM oo joogsanaya

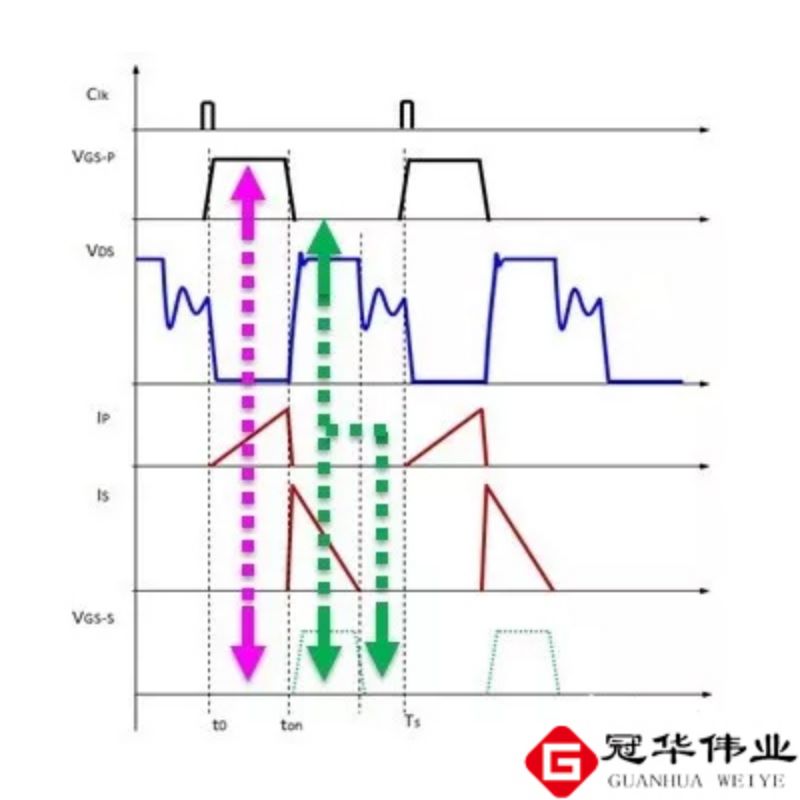

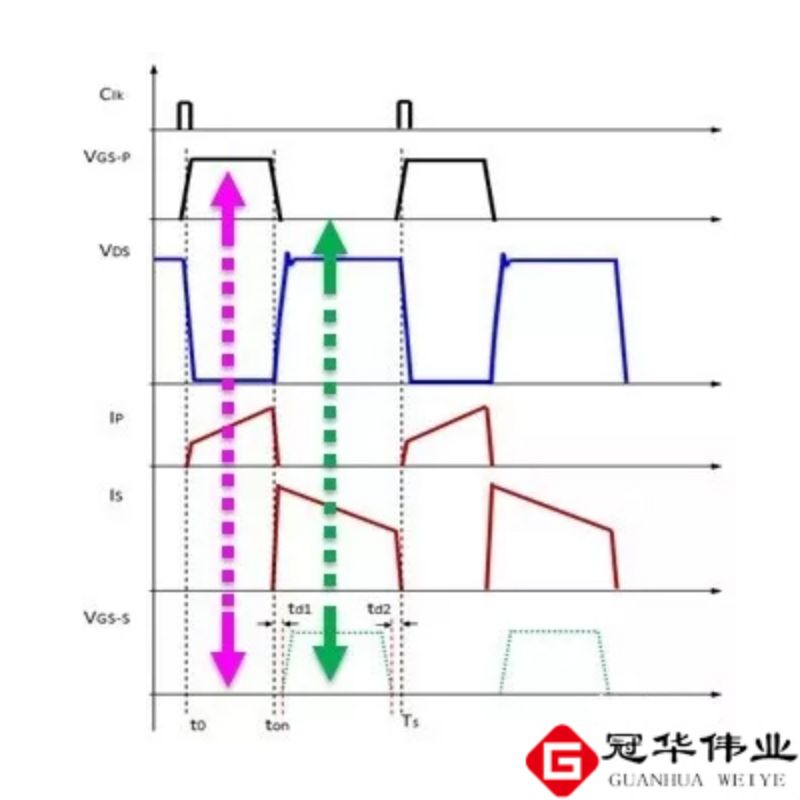

Beddeliyaha duuliyaha wuxuu ku shaqayn karaa qaab CCM joogto ah ama hab DCM oo joogsan. Haddii dabaysha hadda ee heerka sare (sare) gaadho 0 dhamaadka wareegga beddelka, waxa loo yaqaan habka DCM ee joogsan. Haddii wakhtiga dabeyluhu aanu ahayn 0 dhamaadka wareegtada wareejinta, waxa loo yaqaan hab CCM joogto ah, sida ku cad jaantusyada 8 iyo 9.

Waxaa laga arki karaa Jaantuska 8 iyo Jaantuska 9 in xaaladaha shaqada ee sixitaanka synchronous SSR ay ku kala duwan yihiin hababka hawlgalka ee kala duwan ee beddelaha duuliyaha, taas oo sidoo kale ka dhigan tahay in hababka xakamaynta ee saxitaanka isku midka ah ee SSR ay sidoo kale ka duwanaan doonto.

Haddii wakhtiga dhintay la iska indho-tiro, marka lagu shaqaynayo habka CCM ee joogtada ah, sixitaanka isku-dhafka ah ee SSR wuxuu leeyahay laba gobol:

① MOSFET dhinaca hore (primary) korantada sare waa shid, dhinaca sare (labaad) ee toosinta MOSFET waa dansan yahay;

② MOSFET dhinaca hore (primary) ee korantada sare waa dansan yahay, dhanka sare (labaad) ee toosinta MOSFET waa shid.

Sidoo kale, haddii wakhtiga dhintay la iska indho-tiro, hagaajinta isku-dhafka ah ee SSR waxay leedahay saddex gobol marka ay ku shaqaynayso qaabka DCM ee joogsan:

① MOSFET dhinaca hore (primary) korantada sare waa shid, dhinaca sare (labaad) ee toosinta MOSFET waa dansan yahay;

② MOSFET dhinaca hore (primary) ee korantada sare waa dansan tahay, dhinaca sare (labaad) ee toosinta MOSFET waa shid;

③ MOSFET dhinaca hore (primary) korantada sare waa dansan tahay, dhanka sare (sare) ee toosinta MOSFET waa dansan yahay.

5. Dhinaca labaad (sare) hagaajinta isku midka ah ee SSR ee qaabka CCM ee joogtada ah

Haddii beddelaha duuliyaha degdega ah uu ku shaqeeyo habka CCM ee joogtada ah, habka kontoroolka dhinaca aasaasiga ah (primary), dhinaca labaad (sare) hagaajinta isku-dhafka ah MOSFET waxay u baahan tahay calaamad is-waafajin ah oo ka socota dhinaca koowaad (primary) si loo xakameeyo xiritaanka.

Labadan hab ee soo socda ayaa inta badan loo adeegsadaa si loo helo calaamadda wadista isku midka ah ee dhinaca sare (labaad):

(1) Si toos ah u isticmaal dabaysha heerka labaad (sare), sida ku cad Jaantuska 10;

(2) Isticmaal qaybo dheeraad ah oo go'doon ah sida transformers-ka garaaca wadnaha si aad ugu gudbiso calaamada wadista isku midka ah ee ka socota dhinaca hore (primary) una gudubta dhinaca labaad (sare), sida ku cad sawirka 12.

Si toos ah iyadoo la isticmaalayo dabaysha sare (sare) si aad u hesho calaamadda wadista isku midka ah, saxnaanta calaamadda wadista isku dhafka ah aad bay u adagtahay in la xakameeyo, wayna adagtahay in la gaaro hufnaan iyo isku halaynta la hagaajiyay. Shirkadaha qaarkood xitaa waxay isticmaalaan kontaroolayaasha dhijitaalka ah si ay u hagaajiyaan saxnaanta xakamaynta, sida ku cad sawirka 11.

Isticmaalka isbedbedelka garaaca wadnaha si aad u hesho calaamadaha wadista isku midka ah waxay leedahay saxnaansho sare, laakiin qiimuhu waa mid aad u sarreeya.

Habka kontoroolka dhinaca sare (secondary) waxa uu badiyaa adeegsada isbedbedelka garaaca wadnaha ama habka isku xidhka birlabeedka si uu u gudbiyo calaamada wadista isku midka ah ee dhinaca labaad (sare) una gudubta dhinaca hoose (primary), sida ku cad sawirka 7.v

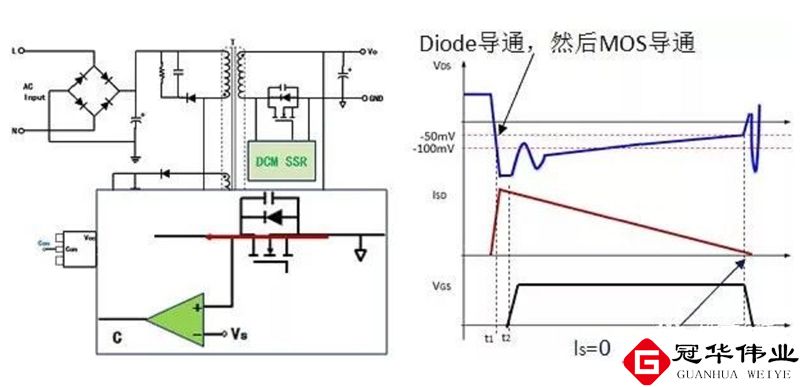

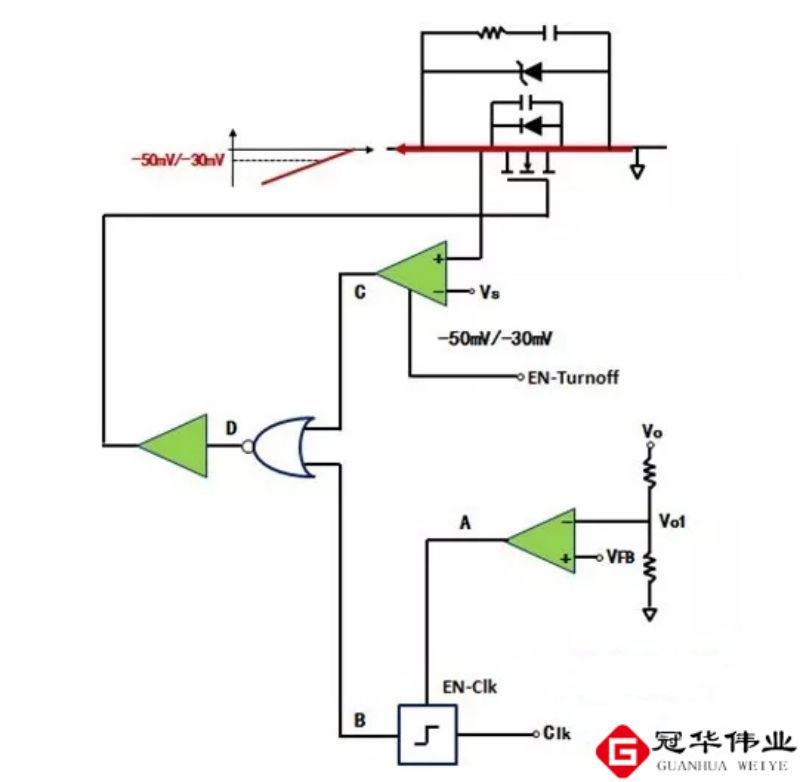

6. Dhinaca labaad (sare) sixitaanka isku dhafan ee SSR ee qaabka DCM ee joogsan

Haddii beddelaha duuliyaha ee degdegga ah u dallacaa uu ku shaqeeyo qaab DCM aan joogsanayn. Iyadoo aan loo eegin habka kontoroolka dhinaca hoose (primary) ama midka labaad (sare) habka kantaroolka, dhibcaha D iyo S ee hagaajinta isku dhafan ee MOSFET si toos ah ayaa loo ogaan karaa loona xakameyn karaa.

(1) Daar sixitaan isku mid ah MOSFET

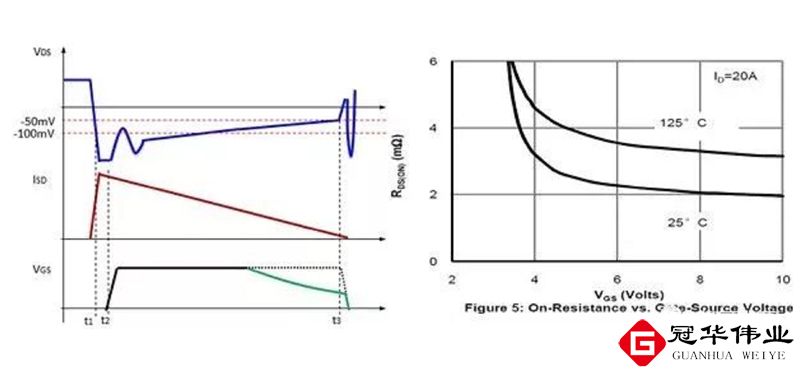

Marka korantada VDS ee toosinta isku-dhafka ah ee MOSFET uu iska beddelo togan una beddelo taban, diode-ka gudaha gudaha ayaa shidma, dib u dhac gaar ah ka dib, toosinta isku-dhafka ah ee MOSFET ayaa shid, sida ku cad sawirka 13.

(2) Deminta MOSFET toosinta isku midka ah

Kadib marka la shido MOSFET toosinta isku xidhan, VDS=-Io*Rdson. Marka heerka sare (sare) uu hoos u dhaco ilaa 0, taas oo ah, marka danabka calaamada ogaanshaha hadda VDS uu ka beddelo taban una beddelo 0, MOSFET isku-dhafka ah ayaa damisa, sida ku cad sawirka 13.

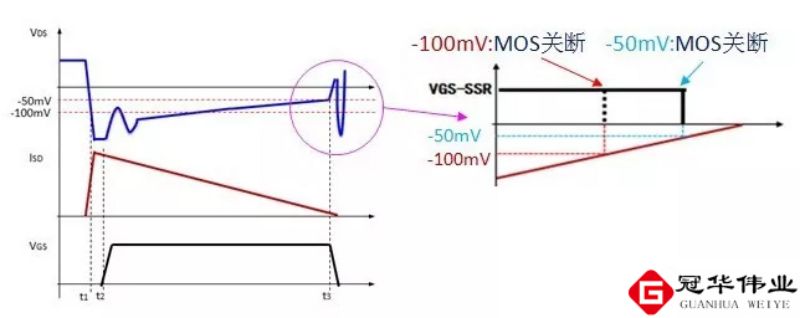

Codsiyada wax ku oolka ah, toosinta isku midka ah MOSFET way damaysaa ka hor inta aanu heerka sare (sare) gaadhin 0 (VDS=0). Qiimaha tixraaca ogaanshaha hadda jira ee ay dejiyeen chips kala duwan ayaa kala duwan, sida -20mV, -50mV, -100mV, -200mV, iwm.

Danab tixraaca ogaanshaha hadda ee nidaamka waa go'an. Way weyn tahay qiimaha saxda ah ee korantada tixraaca ogaanshaha hadda, waa yaraanta qaladka faragelinta iyo saxnaanta ayaa sii fiicnaaneysa. Si kastaba ha ahaatee, marka culeyska wax soo saarka ee hadda Io uu hoos u dhaco, hagaajinta isku dhafka ah ee MOSFET waxay damin doontaa wax soo saar weyn oo hadda socda, iyo diode-keeda gudaha ah ee parasitic-ga ayaa socon doona muddo dheer, sidaas darteed waxtarka ayaa hoos u dhacaya, sida ku cad sawirka 14.

Intaa waxaa dheer, haddii qiimaha buuxda ee danab tixraac ogaanshaha hadda waa mid aad u yar. Qaladaadka nidaamka iyo faragelintu waxay sababi kartaa hagaajinta isku midka ah MOSFET inay damiso ka dib marka heerka sare (sare) ee dabaysha hadda ka badato 0, taasoo keentay rogaal celis socodka hadda, saamaynaya hufnaanta iyo isku halaynta nidaamka.

Calaamadaha ogaanshaha saxda ah ee hadda jira waxay hagaajin karaan hufnaanta iyo isku halaynta nidaamka, laakiin qiimaha qalabku wuu kordhi doonaa. Saxnaanta calaamadda ogaanshaha hadda waxay la xiriirtaa arrimaha soo socda:

① Saxnaanta iyo qulqulka heerkulka ee danab tixraaca ogaanshaha hadda;

② Korontada eexda iyo danab kabista, eexda hadda iyo hadda ka kacda, iyo qulqulka heerkulka cod-weyneeye hadda;

③ Saxnaanta iyo qulqulka heerkulka korantada ee Rdson ee toosinta isku-dhafka ah ee MOSFET.

Intaa waxaa dheer, marka laga eego dhinaca nidaamka, waxaa lagu wanaajin karaa iyada oo loo marayo kantaroolka dhijitaalka ah, beddelidda danab tixraaca ogaanshaha hadda jira, iyo beddelidda toosinta isku-dhafka ah ee MOSFET danab wadista.

Marka culeyska wax soo saarka ee hadda Io uu hoos u dhaco, haddii korantada wadista awoodda MOSFET ay yaraato, MOSFET u dhiganta danab-shirka Rdson ayaa kordha. Sida ku cad Jaantuska 15, waxa suurtogal ah in laga fogaado xidhitaanka hore ee toosinta MOSFET, la dhimo wakhtiga haynta diode-ka dulin, lana wanaajiyo hufnaanta nidaamka.

Waxaa laga arki karaa Jaantuska 14 in marka culeyska wax soo saarka ee hadda Io uu hoos u dhaco, koronta tixraaca ogaanshaha hadda sidoo kale hoos u dhaco. Sidan oo kale, marka wax soo saarka hadda Io uu weyn yahay, korantada tixraaca ogaanshaha hadda ee sare ayaa loo isticmaalaa si loo hagaajiyo saxnaanta xakamaynta; marka wax soo saarka hadda Io uu hooseeyo, korantada tixraaca ogaanshaha hadda hoose ayaa la isticmaalaa. Waxa kale oo ay wanaajin kartaa wakhtiga qabashada MOSFET toosinta isla markaana wanaajin karta hufnaanta nidaamka.

Marka habka kore aan loo isticmaali karin hagaajin, Schottky diodes sidoo kale waxaa lagu xiri karaa si isbarbar ah labada daraf ee isku-dhafka ah ee MOSFET. Ka dib marka MOSFET sixitaan isku mid ah horay loo damiyo, diode Schottky dibadda ah ayaa lagu xiri karaa wheel wheel.

7. Sare (sare) xakamaynta qaabka isku-dhafka CCM + DCM

Waqtigan xaadirka ah, asal ahaan waxaa jira laba xal oo si caadi ah loo isticmaalo oo loogu talagalay dallacaadda degdegga ah ee taleefanka gacanta:

(1) Koontaroolka dhinaca koowaad (primary) iyo qaabka shaqada ee DCM. Dhanka labaad (sare) hagaajinta isku xidhan MOSFET uma baahna calaamad la mid ah.

(2) Xakamaynta dugsiga sare (sare), CCM+DCM qaab hawleed isku dhafan (marka culeyska wax soo saarka uu hoos u dhaco, laga bilaabo CCM ilaa DCM). Dhanka labaad (sare) toosinta MOSFET si toos ah ayaa loo wadaa, mabaadi'da macquulka ah ee shid iyo dami ayaa lagu muujiyey Jaantuska 16:

Daarida toosinta isku-dhafka ah MOSFET: Marka tamarta VDS ee toosinta isku-dhafka ah ee MOSFET ay ka beddesho togan ilaa taban, diode-keeda gudaha ah ayaa shid. Dib u dhac gaar ah ka dib, MOSFET sixitaan isku mid ah ayaa shideysa.

Deminta MOSFET toosinta isku xidhan:

① Marka danab wax soo saarku uu ka yaraado qiimaha go'an, signalka saacada isku midka ah ayaa loo isticmaalaa in lagu xakameeyo daminta MOSFET oo uu ku shaqeeyo qaabka CCM.

② Marka danab wax-soo-saarku uu ka weyn yahay qiimaha go'an, calaamadda saacadda isku-dhafka ah waa la ilaaliyaa oo habka shaqadu wuxuu la mid yahay qaabka DCM. Calaamada VDS=-Io*Rdson waxay xakamaysaa xidhitaanka isku xidhka toosinta MOSFET.

Hadda, qof kastaa wuu ogyahay doorka MOSFET ka ciyaarto dhammaan lacag-bixinta degdegga ah ee QC!

Ku saabsan Olukey

Kooxda xudunta u ah Olukey ayaa diiradda saarey qaybaha 20 sano waxayna xarunteedu tahay Shenzhen. Ganacsiga ugu weyn: MOSFET, MCU, IGBT iyo aaladaha kale. Alaabta wakiilka ugu weyn waa WINSOK iyo Cmsemicon. Alaabooyinka waxaa si weyn loogu isticmaalaa warshadaha militariga, xakameynta warshadaha, tamarta cusub, alaabada caafimaadka, 5G, Internet of Things, guryaha smart, iyo alaabada kala duwan ee macaamiisha elektiroonigga ah. Ku tiirsanaanta faa'iidooyinka wakiilka guud ee asalka ah ee caalamiga ah, waxaan ku saleysannahay suuqa Shiinaha. Waxaan u isticmaalnaa adeegyadeena faa'iidada leh si aan u soo bandhigno macaamiisheena qaybo kala duwan oo teknoolojiyad sare ah oo horumarsan, ka caawinta soosaarayaasha soo saarista alaab tayo sare leh iyo bixinta adeegyo dhamaystiran.